Hi Yakkers,

Well, with the rubbish weather we are having, I thought I’d catch up on the subject of Polycarbonate. You may remember a recent Trip Report from Sunshiner, extolling the virtues of his new GPS holder made, by me, of polycarbonate.

Here it is again, very neat, eh!

If you aren’t familiar with polycarb, I’ll gladly share my knowledge with you.

Most of you are probably aware of Acrylic or Perspex, and that it can be heated and shaped etc. Polycarb was originally marketed as Lexcen, and was touted as being unbreakable. That’s certainly its prime characteristic but, its biggest asset, I think, is that it can be Cold Bent. This means that if you have access to a metal folding machine or something similar, you are on the track to shaping polycarbonate to suit a variety of needs.

Polycarb cuts and drills the same as Perspex. I try to do my cutting on a tungsten tipped saw bench, but a jig-saw or even a hacksaw will work, obviously depending on the size of the job. My original GPS holder was bent up from acrylic, which took a bit of trial and error. Kev’s holder took me about two minutes to do the bends.

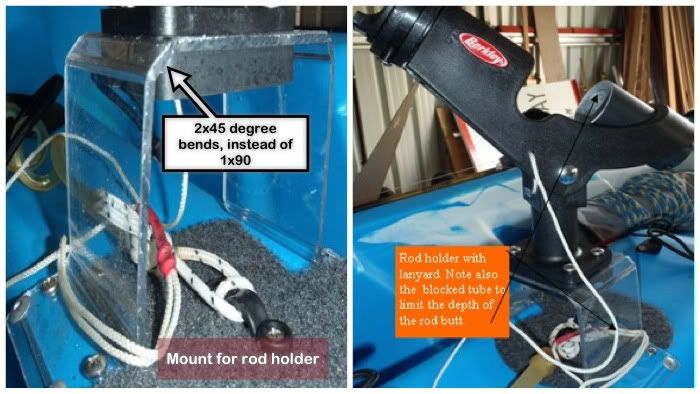

The only drawback with my personal metal folder is that it’s set up for sheet metal, which is anything from .6mm to 1.2mm thick approx. This tends to crease the polycarb when you’re going for a 90deg bend and this is why I have put 2x45deg bends on the rod holder mounts (see pic below). The rod holder in question was used when catching one of the pair of 50cms snapper on my last trip to SR, and worked perfectly. I’m now working on being able to adjust the bender to suit polycarbonate better.

The polycarb mount (left) and the rod holder in place (right)

Polycarb is used by domestic and auto glazing firms and, if they are like me, they will have an offcuts box at a reduced rate. Amateur lure makers often raid these offcut bins for material for their lure bibs.

Most places which carry polycarb would cut to size for you. It is generally available in 3, 4.5 and 6mm thicknesses, although the heavier gauges are obviously harder to bend. Your local sheet metal shop will have an assortment of benders so it might pay to get to know the owner.

Geoff

More from Geoff, 28Jan12

::::::::::

Hi Yakkers,

After reading Jimbo’s comment on the blog, I realized that I needed to go back to the man cave and do some thinking. I need to do some more bending to make my camera holder, a la Sunshiner, and I didn’t want the creasing from my current machine. Also, I need to come up with something portable, so that you guys can benefit, too.

Anyway, the design is done, giving a unit about 300mm long, and able to be clamped into a vice or screwed to the edge of a bench. Since most uses would call for bending pieces up to 150-200mm wide, ie mounting brackets, then that size should work. Three pieces of angle iron is the basis, so watch this space. Any ideas or suggestions would be welcomed before it goes into production.

I’m looking forward to a PC workshop at Jimbo’s.

See you on the water

Geoff Stolberg

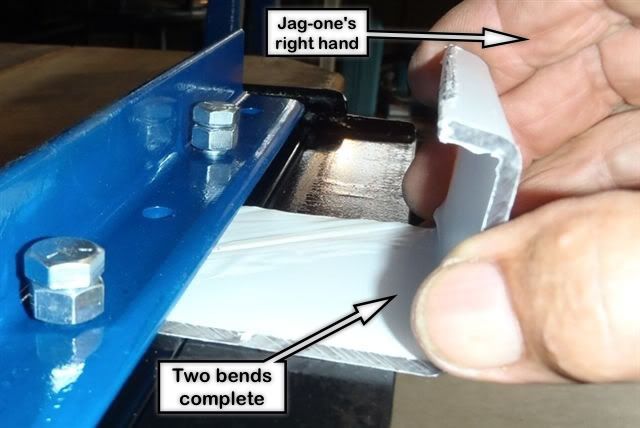

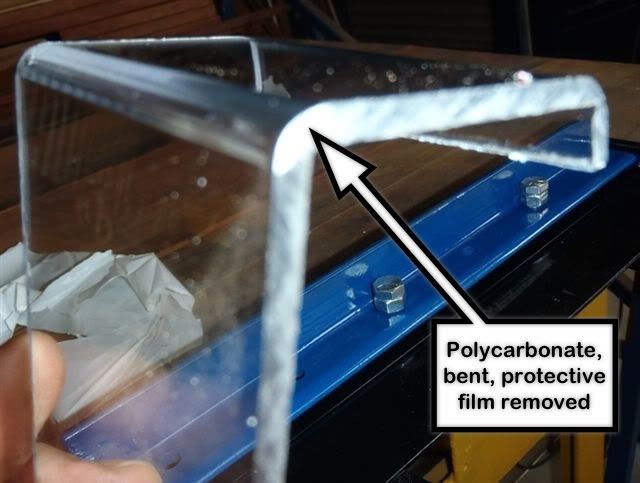

Call Sign ..JaG one

Pics etc added 01Feb12...

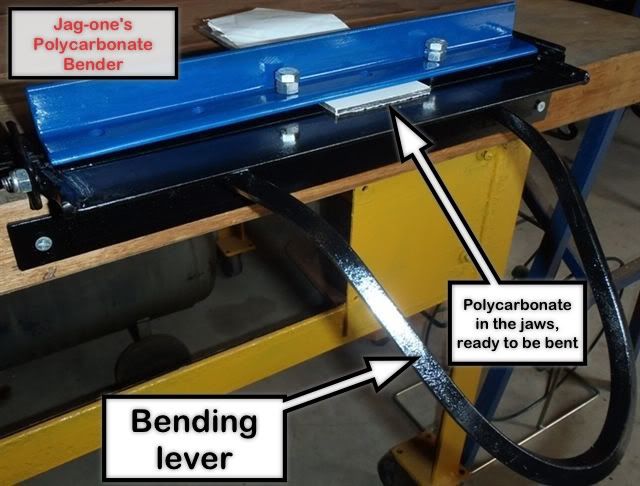

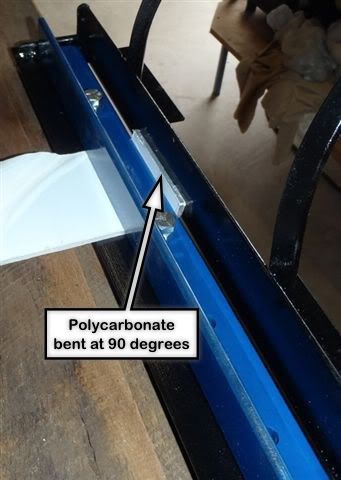

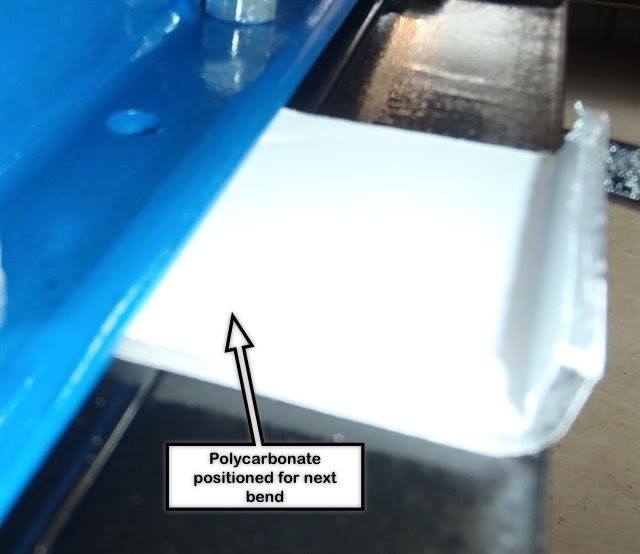

The unit will take up to 270mm wide, which should suit our requirements. It can be screwed to a bench or fitted into a vice. As you can see, I have fitted it to my heavy bench. The weight is only a couple of kilos, so very portable. The bending procedure of any job depends on the shape, so the pics are for example only.

:::::::::

Pics provided by jag-one on 01Feb12 and posted same day. There are six pics below, which, if viewed in sequence as you scroll down, show the device and how it is used. Thanks, Geoff.

::::::::::::

3 comments:

Thanks Geoff - very informative. I never realized polycarbonate could be cold bent. Presumably you need to "overbend" in order to achieve the desired finished angle. I don't have bender, but could you achieve reasonable results using a vice with rounder edge soft jaws made from aluminium or hard wood? Would mind heating using say a hair drier assist the ease of bending?

Having typed this post, have just realized it might have been better to ask these questions via an email. On second thoughts maybe others might be interested in your answers.

Cheers,

Jimbo

Jimbo. Yes, it does require overbending, and the amount of OB depends on the required bend angle. This is the beauty of cold bending,as you can infinitely control the pressure you apply until you get the required bend.

I have never tried heating PC, as there was never a need. Have done plenty with perspex, using a makita hot air gun and firm timber clamped in a vice. You then need a timber "spatula" to hold the bend till it cools.

The biggest problem with a vice bend is the amount of pressure required to get the bend, and getting a tool to apply same. As you can see, this is where a bending press comes into it's own.

Grateful to you for more information.

polikarbon

polikarbon

polikarbon

polikarbon

polikarbon

polikarbon

polikarbon

polikarbon

Post a Comment